- Application: Hatch chicken, duck, goose, pigeon, quail, peacock eggs, etc. for large-scale incubator.

- Feature: Unify stages with automatic control of egg turning and hatching.

- Key words: Single incubator, Multi-stage tunnel incubator.

- Features: High efficiency and save energy.

Single Stage Egg Incubator Introduction

An incubator, as the name suggests, is a device used to hatch various poultry, exotic birds, and other bird species, designed to generate economic benefits. Incubation equipment refers to the collective tools required during the incubation process, including incubators, hatching machines, incubator accessories, specialized hatchery items, heating and humidifying equipment, and various monitoring systems. Among these, the incubator is the most crucial component.

In modern poultry farming, efficient and stable incubation equipment like a poultry incubator is key to improving productivity. Enhancing hatch rates and maintaining consistent quality are crucial aspects. The Single Stage Egg Incubator is an intelligent device specifically designed for efficient incubation, catering to a wide range of needs, from chicken eggs to exotic bird eggs.

Unlike traditional multi-stage incubators, the single-stage incubator places eggs from the same batch into one incubator, following the complete developmental stages of the embryos. Throughout the incubation cycle, the single-stage incubator provides a consistent environment for the batch, including uniform temperature, humidity, and ventilation. This optimized developmental process significantly improves hatch rates and reduces incubation production costs.

Why Choose AGICO Single Stage Egg Incubator?

- Optimized for Commercial Operations

Designed to handle large quantities of eggs within a single cycle, the AGICO single-stage egg incubator ensures environmental consistency throughout the incubation process, making it ideal for industrial-scale hatcheries. All eggs remain at the same developmental stage, simplifying operational planning. By maintaining a stable environment from start to finish, the incubator promotes healthy embryo development, achieving an average hatch rate of over 95%. It is suitable for hatching various poultry eggs, including chicken, duck, goose, and quail eggs, delivering consistently stable results. - Advanced Fully Automated Control System

Equipped with high-precision sensors and automated temperature and humidity control systems, the AGICO incubator offers features like automatic egg turning, real-time monitoring, and remote management. Its efficient air circulation system ensures uniform airflow, preventing cold spots or overheating, making hatchery operations more effortless and efficient. - Energy-Efficient and Eco-Friendly Design

With energy-saving technology, the incubator significantly reduces power consumption, saving electricity without compromising performance. Its durable and environmentally friendly materials ensure stable performance and low maintenance costs, making it ideal for farms looking to minimize their carbon footprint. - Customized Service

We offer customization options for the single-stage incubator based on your production scale and needs. Capacities range from a few hundred to several thousand eggs. Additionally, AGICO provides exceptional customer support, including installation guidance, operational training, and 24/7 technical assistance. - Special Design Features

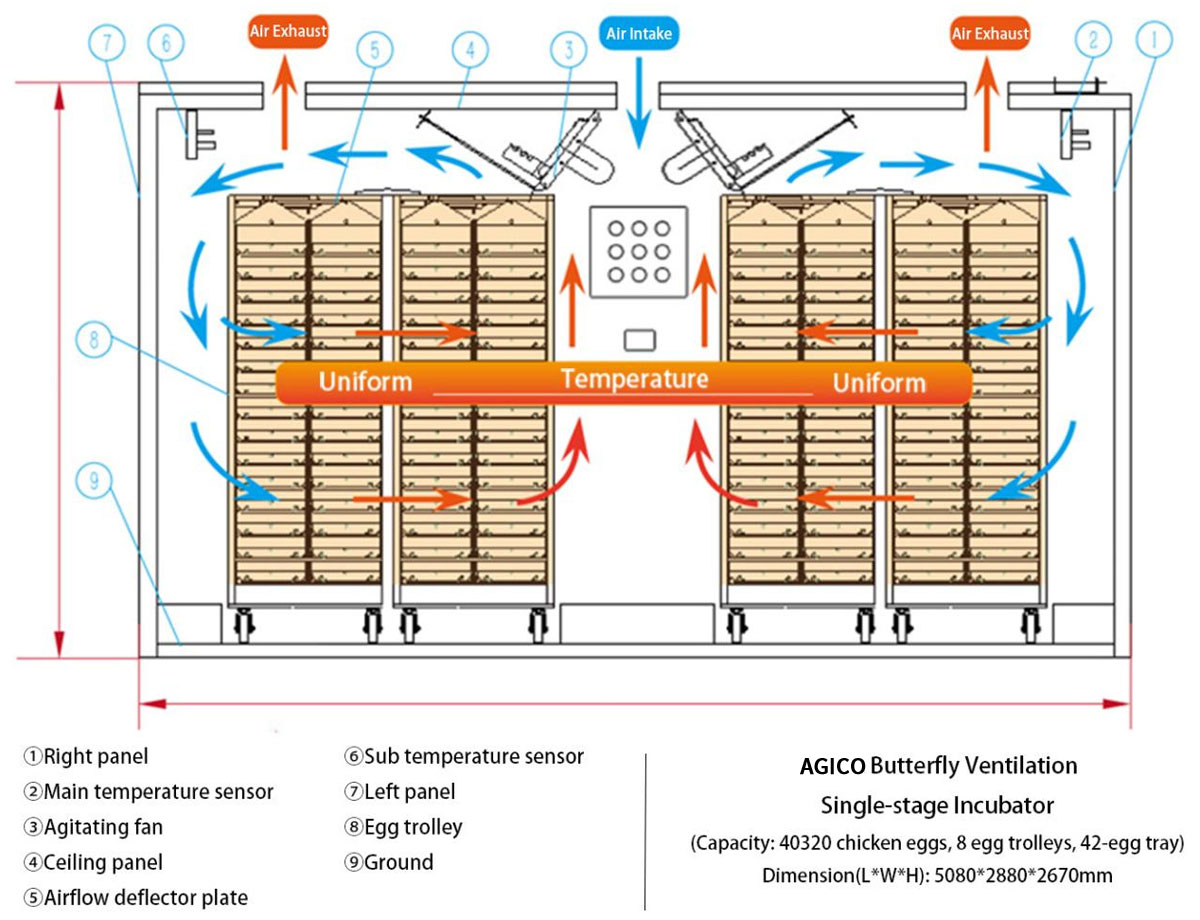

The AGICO single-stage incubator features two rows of back-to-back fans in the central chamber, ensuring air is pushed at an optimal speed toward the sides of the incubator, with short-range airflow evenly penetrating all eggs. Fan speeds are adjusted through a frequency converter based on the incubation stage. Class A cooling coils are located in the central chamber, while Class B cooling coils are positioned between the trolleys. The use of ECM motors enhances energy savings.

Single Stage Egg Incubator Features and Advantages

Higher Hatch Rate

The single-stage incubator provides more uniform and stable incubation conditions, increasing hatch rates by approximately 10%-15%. Through precise temperature and humidity control, the Single Stage Egg Incubator ensures optimal conditions for each egg during the incubation process, significantly enhancing efficiency. As all eggs in the batch are incubated simultaneously, the embryos develop in sync. This simplifies management during processes like transfer to hatching trays, where all embryos are at the right stage for transfer. This improves work efficiency and supports better chick quality.

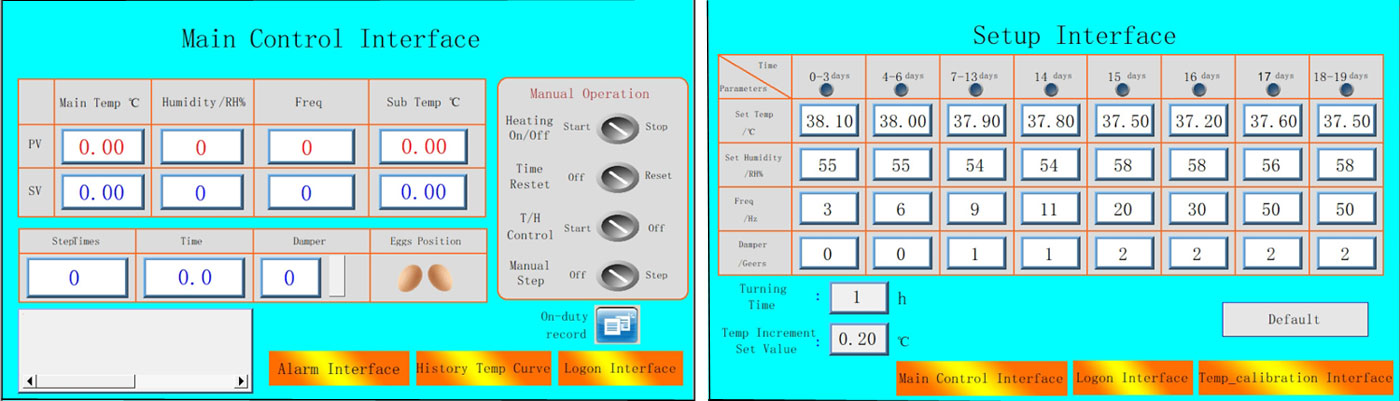

Precise Control System

Equipped with high-sensitivity sensors and an intelligent control system, the single egg incubator achieves temperature accuracy of ±0.1°C and humidity deviation of less than ±2% RH, meeting the incubation needs of different types of eggs. The single-stage incubator can precisely adjust temperature, humidity, ventilation, and egg-turning conditions to suit the specific stage of development for the batch. For instance, during early incubation, when embryos require stricter temperature regulation, the incubator maintains the temperature within the optimal range of 37.8–38.3°C. This ensures uniformly healthy and well-developed chicks.

Energy Efficiency and Sustainability

The incubator incorporates advanced energy-saving designs for low operational energy consumption and features an environmentally friendly shell. By processing a single batch of eggs at a time, it avoids cross-contamination between embryos at different developmental stages, offering a sustainable solution.

User-Friendly Design

With a simple and intuitive interface, the incubator includes a wide-angle transparent observation window, allowing users to monitor the incubation process at any time. An automatic egg-turning function rotates the eggs every 90 minutes, simulating natural conditions to prevent embryos from sticking to the shell. A digital display provides clear information on temperature, humidity, and turning frequency, making operation and management straightforward. Its low investment cost and ease of operation and maintenance make it ideal for beginner farmers.

Safe and Reliable

- The incubator features built-in high-temperature, low-temperature, and humidity deviation alarms to alert users to any anomalies for timely intervention.

- An internal UV disinfection lamp effectively sterilizes the environment, preventing bacterial infections and maintaining a clean incubation space. This reduces the risk of contamination and ensures a safe incubation environment.

Comparison between single stage incubator and multi-stage incubator

Feature | Single Stage Incubator | Multi-Stage Incubator |

Hatching Stages | Single stage | Mixed stages |

Environmental Control | Optimized for specific stages | Must accommodate multiple stages |

Equipment Complexity | Higher | Lower |

Hatch Rate and Quality | Higher | Lower |

Applicable Scale | Large-scale, high-end farming | Suitable for all scales (large, medium, small) |

Initial Investment Cost | High | Moderate or low |

It is important to note that compared to traditional multi-stage incubators, single-stage incubators require more advanced technology, relying on precise environmental control and demanding a certain level of technical knowledge and management skills from operators. The Single Stage Incubator is a highly efficient and precise hatching device designed specifically for large-scale farms or high-end hatching needs requiring a uniform incubation environment.

Although the initial investment cost is higher, the significant long-term benefits, such as improved hatch rates and chick quality, make it a worthwhile choice. It is particularly suitable for batch hatching but less ideal for small-scale or scattered hatching needs. At AGICO, we specialize in providing large-scale poultry farming equipment, including various chicken layer cage products. When paired with a single-stage incubator, our solutions can better serve poultry farmers.

If you are looking for efficient, reliable, and easy-to-operate hatching equipment, the Single Stage Egg Incubator is your best choice! Contact us today to get detailed specifications and pricing information. With cutting-edge technology, reliability, and efficiency, our single-stage incubator is the ideal investment for commercial poultry farms.

Single Stage Incubator Specification

| Model | Type | Capacity | Egg Trolley | Egg Flat | Dimensions(mm) | Fans | Power(KW) 380V50HZ | ||

| Nos. | Capacity | Tiers | Width*Depth*Height | ||||||

| FXTS-20160 | Chick | 20160 | 4 | 5040 | 15 | 42 | 4120*1620*2670 | 3 | 4.5 |

| FXTS-40320 | Chick | 40320 | 8 | 5040 | 15 | 42 | 5080*2880*2670 | 5 | 9.9 |

| FXTS-60480 | Chick | 60480 | 12 | 5040 | 15 | 42 | 6980*2880*2670 | 10 | 12.5 |

| FXTS-120960 | Chick | 120960 | 24 | 5040 | 15 | 42 | 6980*5580*2670 | 20 | 24.5 |

| FXTS(Y)-51840 | Duck | 51840 | 12 | 4320 | 12 | 30 | 8780*2880*2670 | 10 | 12.5 |