Broilers typically reach slaughter weight in about 45 days, so a 45-day chicken cage is essentially a cage used for raising broilers. These broiler cages are designed for efficient broiler farming, providing an appropriate environment and space for the broilers to grow rapidly in a short period. Compared to layer chicken cages, broiler chicken cages are relatively simpler in design, focusing on spaciousness to allow the chickens to move freely and gain weight.

The broiler chicken cages usually feature a multi-layer design to increase the breeding density per unit area. The bottom mesh of the cages is larger, facilitating the dropping and cleaning of chicken manure to reduce the occurrence of diseases. Additionally, each broiler in the cage has more space to move freely, which promotes weight gain. Due to the short breeding cycle of broilers (usually around 45 days), the broiler cage design emphasizes load-bearing capacity and durability. The design of broiler cages focuses on efficiency, practicality, and durability.

Broiler Chicken Cage Design Basic Principles

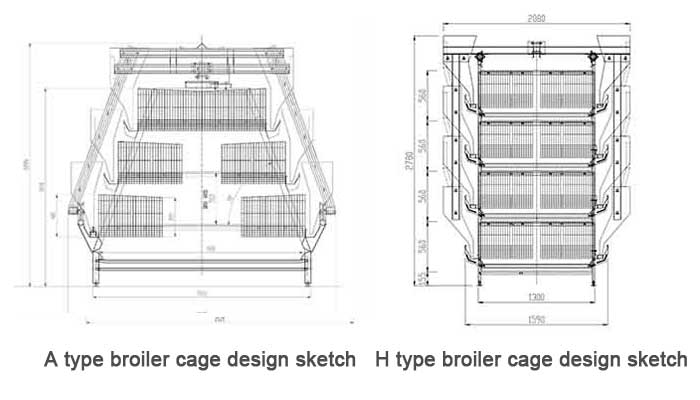

Broiler Cage Structure

The structure of broiler chicken cages should be sturdy and durable, capable of bearing the weight and activities of the flock. High-strength galvanized steel is commonly used due to its excellent anti-corrosion properties and extended lifespan. The design of broiler chicken cages should aim to enhance production performance, welfare standards, and farming efficiency. It is essential to consider the behavioral habits, growth needs, and farming environment of broilers, ensuring they can grow in a comfortable and healthy setting.

Broiler Cage Space

Each broiler requires an appropriate amount of space to ensure free movement while avoiding excessive space that could increase farming costs. Generally, each broiler should have no less than 0.1 square meters of space to meet basic needs such as movement, feeding, drinking, and resting. The internal layout should be rational to prevent interference and fighting among broilers and facilitate management and operations by farming personnel.

Ventilation and Drainage

Broiler cages should have a good ventilation system to maintain fresh and dry air inside the cage, reducing the occurrence of diseases. Additionally, reasonable sanitary facilities such as automatic manure removal systems and drinking systems should be installed to reduce the labor intensity of farming personnel and improve farming efficiency.

Material Selection and Durability

The materials used for broiler cages should be durable, corrosion-resistant, and easy to clean. Common materials include galvanized wire mesh and stainless steel. These materials can withstand the activity pressure of broilers and effectively prevent bacterial growth, ensuring the health of the broilers.

Advanced Broiler Chicken Cage Design Features

Automated Breeding Systems

Modern broiler chicken cage designs typically include automated feeding and drinking systems, manure cleaning, climate and cooling systems, enabling centralized management and automatic control. This not only reduces labor costs and increases productivity but also ensures uniform distribution of feed and water, enhancing breeding efficiency. Additionally, the application of intelligent monitoring systems allows for real-time monitoring of broilers’ growth conditions and environmental parameters such as temperature and humidity, providing scientific decision-making support for farming personnel.

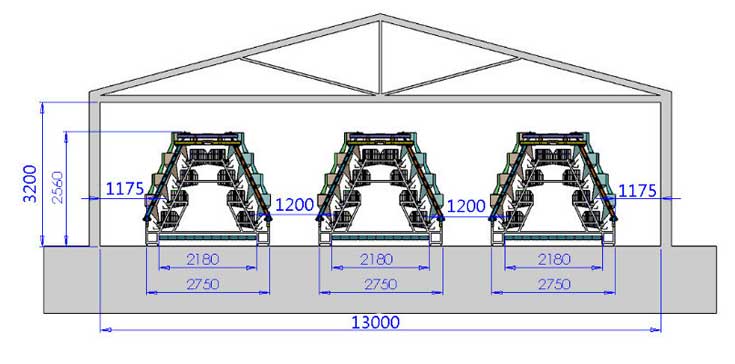

Multi-Layer Design

The multi-layer design of broiler chicken cages allows for the rearing of more chickens in a limited space, improving land utilization. There should be sufficient space between each layer of cages to facilitate chicken movement and management operations. Compared to cage-free chicken house, cage-rearing has a stocking density that is more than three times higher. Typically, broiler cages are designed with three or four layers, with three-layer broiler cages about 60 chickens per unit and four-layer broiler cages about 96 chickens per unit.

Cleaning and Disinfection

Well-designed broiler chicken cages should be easy to clean and disinfect. Movable bottom grids and drawer-type manure collection devices make cleaning more convenient, reducing the breeding of pathogens. Therefore, advanced broiler cage designs are equipped with comprehensive manure handling systems.

Advantages of AGICO Broiler Chicken Cage Design

- Sturdy and Durable. AGICO broiler chicken cages are designed using hot-dip galvanizing technology, making them corrosion-resistant and durable. The lifespan of these cages can reach up to 15-25 years.

- Advanced Technology and Automation. The design of AGICO broiler cages incorporates advanced ventilation, temperature control, and lighting systems. These systems can automatically adjust the internal environment parameters of the cages according to the growth needs of the broilers, providing a comfortable and healthy environment. This environmental control system not only improves broiler production performance but also reduces the incidence of diseases, thereby enhancing farming efficiency.

- Effective Disease Prevention. AGICO broiler cages are designed to prevent chickens from coming into contact with their manure, providing a clean and comfortable environment that effectively prevents infectious diseases, allowing chickens to grow healthier.

- High-Quality Materials. AGICO broiler cages are made from materials such as white PVC feed troughs, 3mm U-shaped galvanized steel frames, ball-valve automatic drinking devices, and white PVC water pipes. These materials are pressure-resistant, heat-resistant, non-deformable, and not easily broken, ensuring the long-term use of the broiler cages.

Choosing the Right Broiler Chicken Cage Design

When selecting a broiler chicken cage design, it is essential to consider factors such as farming scale, site conditions, and budget. It is advisable to choose manufacturers with a good reputation and after-sales service to ensure the quality and longevity of the cages.

After many years of exploration, AGICO has developed broiler cages equipped with automatic drinking systems, automatic ventilation, and automatic manure removal systems, making them highly suitable for broiler farming. We welcome customers to visit and see our products.

A scientific and reasonable broiler chicken cage design is crucial for modern farming. By optimizing the cage structure, space, ventilation, and automation systems, farmers can not only improve farming efficiency but also ensure the healthy growth of chickens, thereby achieving higher economic benefits. We hope this article is helpful to farmers in need of broiler chicken cage designs.