What is egg collecting machine?

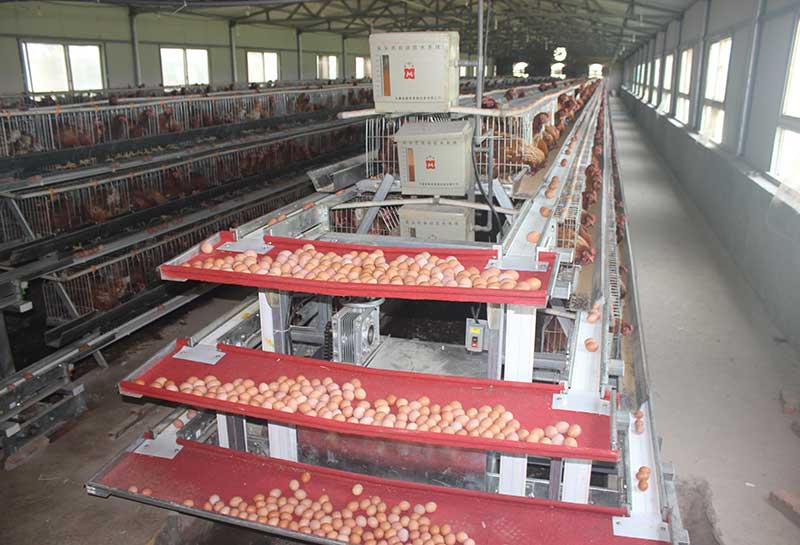

As the name replies, egg collecting machine is used to collect eggs. For raising layer chicken, collecting eggs is one of the most important procedures. So egg collecting machine is necessary for the whole layer chicken cage. Especially for the medium or large scale of chicken raising industry, an automatic egg collecting machine is essential.

Egg collection system is an important part of the automatic breeding equipment for layers, which can realize the automation from egg collection to transmission, it greatly reduce the expenditure of manpower and material resources,and is used in large-scale chicken farms.

Working principle of egg collection system

Why need egg collecting machine?

Compared to manual collecting eggs, egg collecting machine can save time and labor, and reduce the rate of damage eggs and improve the rate of laying. Generally speaking, AGICO egg collecting machine contains easy one and automatic one, they are convenient and time-saving of collecting eggs, which can improve economic benefits and reduce costs and consumption. Greatly improves the degree of automation, improves efficiency, and saves labor costs.

Different models of egg collecting system

On the basis of farmers’ poultry cage scale, the egg collecting method is different. AGICO offers customized egg collecting system like curve and rod conveyors, elevators of egg lifting systems, egg collecting belt etc. For easy egg collecting machine, is mainly fit for 2 or 3 tiers layer chicken cage. While automatic egg collecting is suitable for 4 to 8 tiers layer chicken cage.

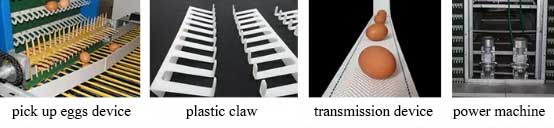

Components of egg collecting machine

An automatic egg collecting system, including imported device, which transports the eggs to the machine. Longitudinal belt conveyors, providing the withdrawal of eggs to the ends of batteries. Transverse and inclined conveyor with lifting mechanism and egg processing table. Equipment that picks up the eggs, export device, buffer device, transmission device, sprocket, and the lifting chain.

- Egg uploading system operates with transmission efficiency including gear reduction drive. The failure rate is low, the service life is long, and the running noise is low, reducing the negative impact of noise on chickens.

- An egg filtration system prevents any broken eggs from being uploaded into the system.

- Egg belt and belt drive system is adopted to effectively set eggs through gear reducer drive, thus ensuring smooth running of eggs when they are on the conveyor belt. The drive rollers are made of high-quality rubber to increase friction with the conveyor belt.

- Has a front-end egg collection system. This ensures that the eggs do not roll out of the system.

- The power distribution system is equivalent to the national standard electrical appliances, designed and produced by professional electrical engineers. It can also be designed according to the electrical control system required by the user.

Working principle of egg collecting system

The belt conveyor is made of polypropylene for good corrosion resistance. They vary in width from 50mm to 70mm. During the transport of the eggs, they move at a speed of one to three meters per minute. So slow that the integrity of the eggs is ensured during transport.

There are many parallel plate-like claws on the egg collector, which are mounted on the lifting chain. These plate-like claws grasp the eggs and guide them smoothly to the end of the chicken cage via the robotic egg collector. Longitudinal conveyor belts have smooth speed regulation and silent transportation, which hardly disturbs the chickens.

Conveyor belts are located on the pallets on each level. Each robotic egg collector has a drive station. When the drive station starts to work, it drives the conveyor belt so that the eggs lying on the conveyor belt arrive precisely on the plastic claws of the collector. The longitudinal belt conveyor consists of numerous plastic claws, and the speed adjustment is smooth, which can be done by turning the control knob on the remote control. During the egg collection process, a longitudinal belt conveyor transports the eggs to the end of the layer chicken cage and then along the inclined conveyor to the egg collection table. A worker at the poultry farm collects eggs.