Hatching Chicken Eggs with Professional Incubator

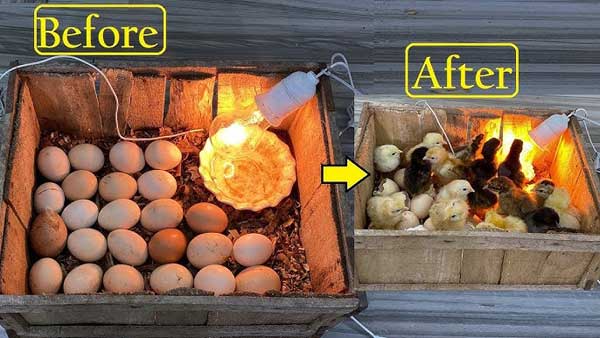

Hatching chicken eggs is a fascinating process, akin to a miraculous journey of life. Within the small shell of an egg lies the promise of new life. From the development of an embryo to the moment a chick breaks free from its shell, every step is filled with wonder and marvel.

In this journey, the role of a poultry incubator is vital. It replicates the natural hatching environment of a mother hen, providing the right temperature, humidity, and ventilation to ensure eggs hatch successfully in a stable environment. The incubator serves as a warm and secure haven, offering a safe, comfortable space for the eggs to hatch.

In modern poultry farming, the efficiency of egg hatching and the quality of chicks directly impact a farm’s productivity and economic performance. By using an incubator for hatching chicken eggs, poultry farmers can precisely control the hatching environment, improving hatch rates and streamlining management processes. Incubators are essential equipment for artificial egg hatching, playing a pivotal role in contemporary poultry farming. They come in various types, such as cabinet incubators, single-stage incubators, and multi-stage incubators, and are designed to regulate temperature, humidity, and ventilation with precision.

The Importance of Temperature, Humidity, and Ventilation

- Temperature: Temperature is one of the most critical factors in hatching. Typically, the ideal temperature for chicken egg hatching ranges between 37.5°C and 38.5°C (99.5°F to 101.3°F). Deviations from this range can hinder embryo development and lead to unsuccessful hatching.

- Humidity: Equally important is humidity. During the early stages of incubation, humidity levels should be maintained between 50% and 60% to prevent excessive moisture loss, which could dehydrate the egg whites and damage the embryo. In the final days of hatching, humidity should be increased to 65% to 75%, facilitating the chick’s ability to break through the shell.

- Ventilation: Proper airflow ensures that the developing embryo receives adequate oxygen, which is essential for its growth and survival.

Inside the incubator, eggs undergo various stages of development. From the initial stages of cell division and organ formation to the later phases when the embryo matures, forming feathers and bones, every step demands careful attention. Regular turning of the eggs is also necessary to ensure uniform heating and to promote healthy embryonic development.

When the hatching process is complete, the chicks emerge from their shells, showcasing the vitality of new life. At this point, appropriate care is essential to ensure their health and growth. Providing a warm environment, clean water, and suitable feed helps the chicks adapt to their new surroundings and thrive.

An incubator is not merely a tool for hatching eggs but a critical component of modern poultry farming. By ensuring precise control over environmental factors like temperature, humidity, and ventilation, incubators make it possible to achieve higher hatch rates and produce healthy, robust chicks. Whether you’re a small-scale farmer or managing a large poultry operation, selecting the right incubator for hatching chicken eggs is key to your success.

Through the use of advanced incubators and meticulous care during the hatching process, poultry farmers can witness the incredible journey of life unfold—one egg at a time.

Why Choose an Incubator for Hatching Chicken Eggs?

While traditional natural hatching methods have historical advantages, they are limited by the number of hens, climatic conditions, and operational complexities, making them less suitable for modern large-scale farming. In contrast, incubators simulate the natural hatching environment of a hen, providing stable temperature and humidity, precise ventilation, and automatic egg-turning functions, making hatching more efficient and reliable.

Key Advantages of Using an Incubator

- Improved Hatch Rates

Advanced incubators can achieve hatch rates of over 90%, significantly reducing the waste of fertile eggs. - Time and Labor Savings

Fully automated incubators can adjust temperature and humidity levels and turn eggs at scheduled intervals, greatly reducing the workload for poultry farmers. - Year-Round Operation

Incubators are unaffected by seasonal and climatic changes. Whether in the coldest winter or the hottest summer, they can maintain an optimal hatching environment.

By using an incubator, poultry farmers can overcome the challenges of traditional methods and achieve consistent, efficient, and high-quality results, making it an indispensable tool for modern poultry farming.

How to Choose the Right Incubator?

The market offers a wide variety of incubators for hatching chicken eggs, ranging from small household incubators to large-scale commercial poultry incubators. Choosing the right model depends on your specific needs.

Hatching Capacity

Select an incubator for hatching chicken eggs based on the size of your operation. Small-scale family farms may opt for incubators with a capacity of 20-100 eggs, while medium to large farms require professional models capable of holding over 500 or even 1,000 eggs.

Automation Features

High-automation incubators are ideal for large-scale farming. Features like automatic egg turning, precise temperature, and humidity control, and alarm systems significantly improve operational efficiency.

Eco-Friendly and Energy-Saving Design

Choose incubators made from eco-friendly materials with energy-saving designs. These not only reduce energy consumption but also align with modern sustainability goals.

After-Sales Support

Check whether the supplier provides installation guidance, operational training, and long-term technical support, which are crucial for the effective use and maintenance of the equipment.

At AGICO, we offer a wide range of incubators to meet diverse needs—from basic models to advanced options like single-stage incubators, 500-egg incubators, and cabinet-style incubators. Our goal is to provide tailored solutions for poultry farmers of all scales.

Hatching Chicken Eggs with Incubator Process

Hatching chicken eggs with an incubator may seem straightforward, but it requires careful attention to key steps to ensure a high hatching rate and healthy chicks.

- 1. Selecting Fertile Eggs: Selecting quality eggs is crucial for successful hatching. Freshness is key, as fresher eggs have a higher hatch rate. Ideally, eggs should be incubated within 7 days of being laid; the longer they are stored, the lower the hatch rate. When choosing eggs, look for these qualities: smooth, evenly textured shells, proper size, and oval shape, free of cracks, dirt, or other defects. Eggs meeting these criteria provide a solid foundation for hatching success. Additionally, before placing the eggs in the incubator, thoroughly clean and disinfect the machine with a suitable sanitizer to eliminate bacterial contamination.

- 2. Setting Incubation Conditions: Before starting, preheat the incubator at least 24 hours in advance to ensure it reaches the optimal temperature, typically between 37.5 – 38°C (99.5 – 100.4°F). Humidity is equally critical, starting at 50% – 60% during the early stage and increasing to 65% – 75% during the later stage. When placing the eggs: position the pointed end downwards. leave enough space between eggs to ensure proper airflow, avoid overcrowding, as it can hinder air circulation and development.

- 3. Managing the Incubation Process: During incubation, consistent monitoring and care are essential. Turn the eggs 3-5 times daily to ensure uniform heating and prevent the embryo from sticking to the shell. Use a candling device on days 7 and 14 to check embryo development. Remove any non-viable eggs. Regularly record and adjust temperature and humidity to maintain optimal conditions. Ensure adequate airflow inside the incubator to provide sufficient oxygen for the developing embryos. These practices support healthy embryo development and prepare for the hatching stage.

- 4. Hatching Stage: From day 18 to day 20, move the eggs to the hatching area. Reduce the temperature to 36.8°C – 37.2°C (98.2 – 99°F). Increase humidity to 75%. Stop turning the eggs to allow the embryos to settle and prepare for hatching. During this phase, embryos require a calm environment to complete development and break through the shells.

As a professional poultry farming equipment supplier, AGICO offers comprehensive farming solutions, including high-quality chicken cages and advanced incubator equipment. Our Single Stage Egg Incubators and multi-stage incubators are widely used for hatching eggs of chickens, ducks, geese, and other poultry, earning praise from customers worldwide.

We provide a full range of products, from small home-use incubators to large-scale commercial incubators. Our fully automated systems ensure efficient and reliable operation. Robust after-sales services include installation guidance, operation training, and 24/7 technical support. In addition to delivering high-quality products, our pricing is highly competitive in the market.

By using modern incubation equipment, such as an incubator for hatching chicken eggs, farmers can achieve a more efficient and scientific farming process. This not only ensures the quality of chicks but also reduces costs and increases economic benefits.

If you are interested in hatching chicken eggs with an incubator or are looking for professional hatching equipment, contact our team today to find the perfect incubation solution for your needs!