When it comes to successful egg production, choosing the right layer poultry cage design is critical. Whether you’re managing a small-scale farm or a large commercial operation, the layout and functionality of your chicken cages can directly impact hen health, egg quality, and overall profitability. In this guide, we’ll explore the key features of effective cage design, industry trends, and what to look for when choosing equipment for your layer operation.

What is Layer Poultry Cage Design?

Layer poultry cage design refers to the engineering and layout of cages specifically built to house laying hens. These cages are optimized to support egg-laying behavior, minimize egg breakage, and maintain bird health over long production cycles.

Unlike broiler cages—which are designed to maximize weight gain in a short period—layer cages are built with a long-term focus, emphasizing comfort, space efficiency, and egg collection efficiency.

Key Features of a High-Quality Layer Cage Design

Sloped Cage Floors

The floor of each cage is slightly sloped, allowing eggs to roll gently into a collection tray. This reduces the risk of breakage and prevents hens from stepping on the eggs.

Durable, Corrosion-Resistant Materials

Since layer hens can stay in the same cage for over a year, using galvanized or PVC-coated wire helps prevent rust, ensuring longevity and hygiene.

Adequate Space Per Bird

Optimal layer cage design follows animal welfare guidelines, providing enough space per hen to stand, feed, and move comfortably. Overcrowding can reduce egg production and increase stress levels.

Automated Feeding and Watering Systems

Modern cages are equipped with automatic feeders and nipple drinkers, ensuring consistent nutrition and hydration while reducing labor costs.

Efficient Manure Removal Systems

A good cage system includes manure belts or scrapers to keep the environment clean, reducing ammonia levels and disease risk.

Customizable Tiers and Layouts

Layer cages are often stackable in 2–5 tiers to maximize space usage. The layout can be customized based on the size of your operation.

Benefits of a Well-Designed Layer Cage System

- Increased Egg Production: Hens in well-maintained cages are less stressed and more productive.

- Higher Egg Quality: Eggs are cleaner and less likely to be cracked or broken.

- Improved Hygiene: Automated waste removal systems create a cleaner, healthier environment.

- Labor Efficiency: Automation reduces manual labor for feeding, cleaning, and egg collection.

- Cost-Effectiveness: Long-term savings through durability and increased output.

Things to Consider When Choosing a Layer Cage

- Bird Capacity: Determine the number of birds you plan to raise and choose a cage size accordingly.

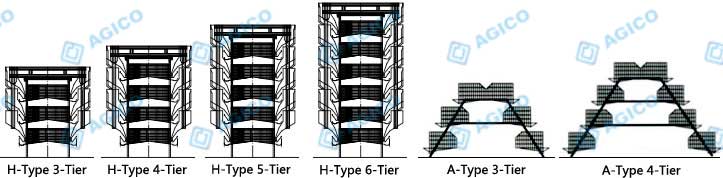

- Cage Type: Consider A-type (stair-step) or H-type (vertical stack) cage systems depending on space and automation needs.

- Climate Adaptation: In hot climates, good ventilation and spacing are crucial.

- Automation Compatibility: Ensure the system integrates with automatic egg collectors, feeders, and waste removal machines.

Trends in Layer Poultry Cage Design

Battery Cage Alternatives: Enriched colony cages and aviary systems are gaining attention in markets with strict animal welfare regulations.

Smart Farming Integration: IoT-based monitoring systems can now track feed, water intake, and hen behavior in real-time.

Sustainable Materials: Eco-friendly and recyclable cage components are becoming more popular.

Key Differences Between Broiler and Layer Poultry Cage Design

When it comes to poultry farming, broiler cages and layer poultry cages differ significantly in their design, function, and management approach. Understanding these distinctions is crucial for selecting the right cage system to optimize production and profitability.

Purpose & Function

Broiler Cages: Specifically designed for raising meat chickens, the goal is to promote rapid weight gain in a short cycle (usually 45 days) before slaughter.

Layer Cages: Tailored for laying hens, with an emphasis on consistent and high-yield egg production over a much longer period, often more than a year.

Cage Structure & Layer Cage Design

Broiler Cages: Simpler in structure with a focus on spaciousness to allow movement and facilitate growth. Often built in multiple tiers to increase density per square meter. Feature larger mesh on the cage floor for better manure drop and easier cleaning, helping to reduce disease risk.

Layer Cage Design: More complex, focusing on bird comfort and maximum egg-laying efficiency. The front floor usually features a sloped wire mesh, allowing eggs to roll safely into collection trays—preventing breakage from stepping. Typically equipped with automatic systems for feeding, drinking, egg collection, and waste removal to streamline management and improve egg quality.

Space Allocation

Broiler Cages: Simpler in structure with a focus on spaciousness to allow movement and facilitate growth. Often built in multiple tiers to increase density per square meter. Feature larger mesh on the cage floor for better manure drop and easier cleaning, helping to reduce disease risk.

Layer Cage Design: More complex, focusing on bird comfort and maximum egg-laying efficiency. The front floor usually features a sloped wire mesh, allowing eggs to roll safely into collection trays—preventing breakage from stepping. Typically equipped with automatic systems for feeding, drinking, egg collection, and waste removal to streamline management and improve egg quality.

Management Requirements

Broiler Cages: Simpler in structure with a focus on spaciousness to allow movement and facilitate growth. Often built in multiple tiers to increase density per square meter. Feature larger mesh on the cage floor for better manure drop and easier cleaning, helping to reduce disease risk.

Layer Cage Design: More complex, focusing on bird comfort and maximum egg-laying efficiency. The front floor usually features a sloped wire mesh, allowing eggs to roll safely into collection trays—preventing breakage from stepping. Typically equipped with automatic systems for feeding, drinking, egg collection, and waste removal to streamline management and improve egg quality.

Production Cycle

Broilers: Raised for about 45 days before being sent for processing.

Layers: Have a production cycle of a year or longer, with peak laying periods requiring precise management.

Practices in Layer Poultry Cage Management

Proper layer cage design alone isn’t enough—it must be paired with scientific management for optimal performance:

Cleanliness and Biosecurity

Maintain sanitary conditions in chicken houses and cages. Conduct routine cleaning, disinfection, and proper manure disposal. Temperature and humidity must be regulated—especially during winter—while ensuring adequate ventilation to avoid harmful gas build-up (e.g., ammonia).

Lighting Management

Light greatly affects egg-laying. Controlled artificial lighting stimulates hormone secretion and stabilizes laying cycles. Install bulbs every 3 meters inside the coop and set a consistent light program. Proper lighting can also promote earlier sexual maturity in pullets, boosting productivity.

Reducing Stress in Laying Hens

Laying hens are sensitive to stress. Any environmental change may lead to decreased egg production. To reduce stress:

- Avoid loud noises and animal intrusions.

- Keep work routines and personnel consistent.

- Ensure stable power and water supplies.

- Gradually adjust feed formulas and avoid abrupt dietary changes.

Key Considerations for Layer Cage Setup

Equipment Selection

Choosing the right layer poultry cage system is foundational. Common cage types include: H-type (stacked) for large-scale, high-density farming. A-type (stepwise) for medium-sized operations.

Reliable cages should include: Sloped floors for egg collection., Corrosion-resistant materials. Compatibility with automation (e.g., feeding, egg collecting, manure removal). Always buy from a reputable cage manufacturer to reduce disease risk and ensure long-term durability.

Stocking Density

Follow stocking guidelines according to breed. Overcrowding can lead to uneven growth, feather loss, aggression, and reduced laying rates. Adequate space is essential for uniform development and strong immune function.

Proper Ventilation

Ventilation is as critical as temperature control. Fresh air removes moisture, heat, ammonia, and dust, while supplying oxygen to support metabolism and growth. Poor ventilation can cause diseases like emphysema, pulmonary edema, and other respiratory issues.

A well-thought-out layer poultry cage design is essential for a productive and profitable egg farming business. From ensuring hen welfare to maximizing efficiency, every detail matters. When selecting cages for your poultry farm, always consider durability, automation compatibility, and the specific needs of your birds.

At AGICO, we offer modern, customizable layer cage systems designed for optimal performance and long-term reliability. Contact us today for expert advice and tailor-made solutions to elevate your egg production.

If you’re looking to invest in advanced layer poultry cage systems or broiler cage setups, visit AGICO — your one-stop destination for high-quality poultry equipment, automatic feeding lines, and complete poultry house solutions.