Poultry farming equipment plays a crucial role in the entire poultry farming process. Whether a large-scale or small-scale poultry farm, choosing the right poultry farming equipment list is essential. In this article, you will learn about the crucial poultry farming equipment list and the considerations to keep in mind when selecting list of equipment used in poultry farming.

Poultry Farming Equipment List

The poultry farming equipment list includes, but is not limited to, the following key equipment.

Chicken layer Cages

Chicken layer cages are used for housing poultry. Depending on the farming stage (such as brooding, rearing, or laying) and scale, choose the appropriate type and size of chicken cages. The chicken layer cages can be made of wire mesh or plastic, with a specific choice depending on farming needs and budget. AGICO offers various types of chicken cages for customers to choose from, such as A-type chicken layer cages, H-type chicken layer cages, A-type broiler cages, H-type broiler cages, pullet cages, etc. According to models, capacity, and cage sizes, there are different types of chicken cages. For example, chicken capacity is divided into 48, 96, 120, 160, and 200 birds per cage. Because of the proper installation height and easy operation, 3 tiers and 4 tiers of chicken cages are commonly used by customers.

Poultry Farming Feeding Equipment

Feeding equipment includes feed troughs and automatic feeding systems for distributing feed. Automatic feeding systems can improve feeding efficiency and reduce labor costs. Feed troughs are the primary feeding equipment, and the type chosen depends on the farming method (such as battery cage or cage-free chicken house). The design of the feed trough is crucial to reducing feed waste.

Poultry Farming Drinking Equipment

Providing sufficient water is essential for poultry health. Common drinking equipment includes nipple drinkers and V-shaped water troughs, the latter needing regular cleaning to prevent bacterial growth. Nipple drinkers save water and are hygienic, while V-shaped water troughs are easier to clean and manage.

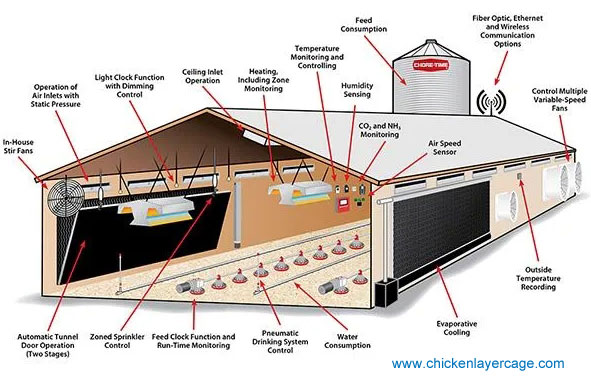

Poultry Farming Ventilation Equipment

Good ventilation is crucial for maintaining air quality and temperature control in poultry houses. Ventilation equipment can include cross ventilation and longitudinal ventilation systems, with the latter proving to be more effective in avoiding dead zones and cross-infections.

Poultry Farming Heating Equipment

To maintain the appropriate temperature inside the poultry house, you can choose electric heating, water heating, or coal stoves for heating and insulation. While coal stoves are cost-effective, they pose safety and environmental concerns. Therefore, it’s recommended to use electric or water heating, ensuring the poultry house is well insulated.

Poultry Manure Removal System

Effective manure cleaning is vital for maintaining a hygienic farming environment and reducing the spread of diseases. You can opt for manual cleaning or mechanical manure cleaning systems, with the latter significantly improving efficiency. So for large scale poultry farms, mechanical poultry manure removal system is popular.

Egg Collection Equipment

For laying poultry or chicken layer cages, egg collection equipment can increase the efficiency of collecting eggs and reduce the breakage rate. It is quite important for laying poultry farming.

Incubation and Brooding Equipment

Includes poultry incubators and brooding cages, used for hatching and rearing chicks.

Lighting Equipment

Controls the duration and intensity of light, affecting poultry growth and egg-laying cycles.

Harmless Treatment Equipment

Used for disposing of diseased or dead poultry, preventing the spread of diseases, and protecting the environment and human health.

When selecting and configuring these lists of equipment used in poultry farming, it is important to consider the scale of the farm, economic conditions, local climate conditions, and the species and growth stages of the poultry. Proper poultry farming equipment and layout can significantly improve farming efficiency, reduce costs, and ensure the health and productivity of the poultry. AGICO provides a detailed and comprehensive poultry farming equipment list. If you are interested, please check out our latest poultry farming equipment list and enjoy limited-time discounts! For any inquiries, contact our experts for customized equipment recommendations.

Poultry Farming Equipment Market Analysis and Trends

In 2023, the global poultry farming machinery market reached a size of 3.03 billion USD. with the Chinese poultry farming machinery market accounting for 876.24 million USD. By 2029, the global market size is expected to grow to 29.734 billion yuan, with an estimated compound of 4.08 billion USD, annual growth rate of 5.2%. In recent years, the poultry farming equipment industry has transitioned from traditional to modern and intelligent farming, driven by the development of modern agricultural technologies and the widespread adoption of large-scale farming. The application of advanced equipment such as automated feeding systems, environmental control systems, and disease monitoring systems has significantly improved farming efficiency, reduced labor intensity, and enhanced poultry health and product quality.

Criteria for Selecting Poultry Farming Equipment

Choosing the right poultry farming equipment is a critical investment decision that requires careful consideration of various factors to ensure that the poultry farming equipment list meets the farm’s needs and enhances production efficiency. Selecting appropriate poultry farming equipment is a vital step in establishing a successful poultry farm. Below are some factors to consider when choosing poultry farming equipment.

Functionality and Applicability of the Equipment

- Identifying Needs: First, you must clearly define the specific needs of the farm. For instance, the farm’s scale, the type of poultry (e.g., chickens, ducks, geese), and production goals will all influence poultry farming equipment selection. For example, automatic feeders are suitable for large-scale farms, while smaller farms may require more flexible manual equipment.

- Functional Versatility: Modern poultry farming equipment typically offers multiple functions, such as automatic feeding, temperature control, and humidity management. Selecting fully functional poultry farming equipment can increase the farm’s automation level and reduce labor input. Ensure that the equipment’s features align with the farm’s actual needs, such as whether an automatic feeding system suits your farming scale or if climate control equipment can operate effectively in your climate conditions.

Quality and Durability of the Equipment

- Materials and Craftsmanship: The quality of the poultry farming equipment, including the materials and manufacturing process, directly affects its lifespan. Choose poultry farming equipment made of corrosion-resistant, durable materials, with a sturdy structure and fine workmanship, to reduce the frequency of repairs and replacements. Poultry farming equipment must be durable and capable of withstanding harsh conditions within the farm. Equipment made from high-quality materials will last longer. Although the initial investment may be larger, the return on investment (ROI) is higher, and high-quality equipment can be optimally adjusted to your specific situation.

- Manufacturing Process: The manufacturing process of the poultry farming equipment directly affects its durability. Selecting well-crafted, finely made equipment can reduce the likelihood of malfunctions during use, thereby lowering maintenance costs. Prioritize equipment with a good market reputation and brand recognition, as these brands typically offer better quality control and after-sales service.

Ease of Use

- Simplicity of Operation: The poultry farming equipment should be as simple to operate as possible to reduce operational complexity and errors. For large farms, poultry farming equipment with a high degree of automation can significantly improve production efficiency. The easier the equipment is to use, the less chance there is for mistakes, and the shorter the training period for employees.

- Ease of Maintenance: Poultry farming equipment maintenance is equally important. Choosing poultry farming equipment that is easy to disassemble, clean, and maintain can extend its service life and reduce the frequency of malfunctions.

Energy Consumption and Cost-Effectiveness

- Energy Consumption Assessment: Some poultry farming equipment consumes large amounts of electricity or fuel during operation, so it’s essential to consider its energy consumption level when making a selection. Energy-efficient equipment may have a higher initial cost but can significantly reduce energy expenses over the long term.

- Long-Term Costs: In addition to the initial purchase price, consider the long-term costs of using the poultry farming equipment, such as maintenance fees, spare part costs, and energy consumption. A comprehensive cost-benefit analysis can help you choose the most economically viable equipment.

Safety

- Safety for Personnel and Animals: The poultry farming equipment’s design should prioritize the safety of both workers and poultry. For example, choose equipment with safety features to prevent accidents during operation.

- Emergency Functions: For critical poultry farming equipment such as ventilation and water supply systems, select those with emergency shutdown and alarm functions to ensure a prompt response in case of emergencies, thereby minimizing losses.

After-Sales Service and Support

- After-Sales Guarantee: Understand the after-sales services provided by the poultry farming equipment supplier, such as warranty periods, maintenance support, and emergency repair services. High-quality after-sales service can ensure the long-term stable operation of the equipment, reducing production losses due to malfunctions.

- Technical Support: When purchasing complex equipment, consider whether the supplier provides technical support and training. Ensure that you can receive professional guidance from the supplier during poultry farming equipment’s installation and commissioning. The availability of spare parts is another important consideration. Ensure that the equipment you choose has a stable supply of spare parts so that components can be promptly replaced in case of equipment failure, minimizing downtime.

Space Considerations

- The size of the farm (in terms of the number of poultry) is an important factor when purchasing poultry equipment. The equipment selected should be suitable for the farm’s actual size to ensure efficiency and cost-effectiveness. Additionally, consider the specific type of poultry being raised, as there may be differences in equipment for raising chickens versus ducks or geese.

Legal and Environmental Requirements

- Legal Compliance: Ensure that the poultry farming equipment purchased complies with local laws and regulations, such as hygiene standards and safety requirements. Some countries or regions have high environmental standards for farming equipment, so it’s important to understand these requirements in advance and ensure that the equipment is compliant.

- Environmental Considerations: Choose poultry farming equipment that is more environmentally friendly in design and use, such as energy-efficient and low-pollution equipment. This not only meets environmental standards but also helps save costs in the long run.

By carefully considering the factors outlined above, you can select the most suitable poultry farming equipment that will not only increase production efficiency but also effectively control costs, thereby enhancing the productivity and profitability of the farm.